HS.Equipment can be of service for:

- Annual Crane Survey

- 5-yearly Crane Survey

- Crane operator instruction

- Load – and Overload tests on site

- Spare parts and crane maintenance kits.

- Upgrade of crane with winch, radio remote control system or other crane accessories

- Renew of hydraulic hoses, winch wire ropes

- Supply of hydraulic power pack or spare parts for power packs

- Recommended spare parts kits

- Crane retrofit

HS.Equipment service engineers are trained and qualified to commission newly installed HS.MARINE cranes, instruct crane operators and provide maintenance and repairs of HS.Marine cranes in operation.

Worldwide and simultaneous service assistance can be handled despite of the light company structure. HS.Equipment can independently coordinate reliable and efficient service assistance using its local service team, HS.MARINE engineers and HS.MARINE’s local distributor and its whole supply chain.

Our service engineers are trained for operating our cranes, working in height and offshore.

In case you need our support, please contact us:

by filling in the form in our

Contact Page

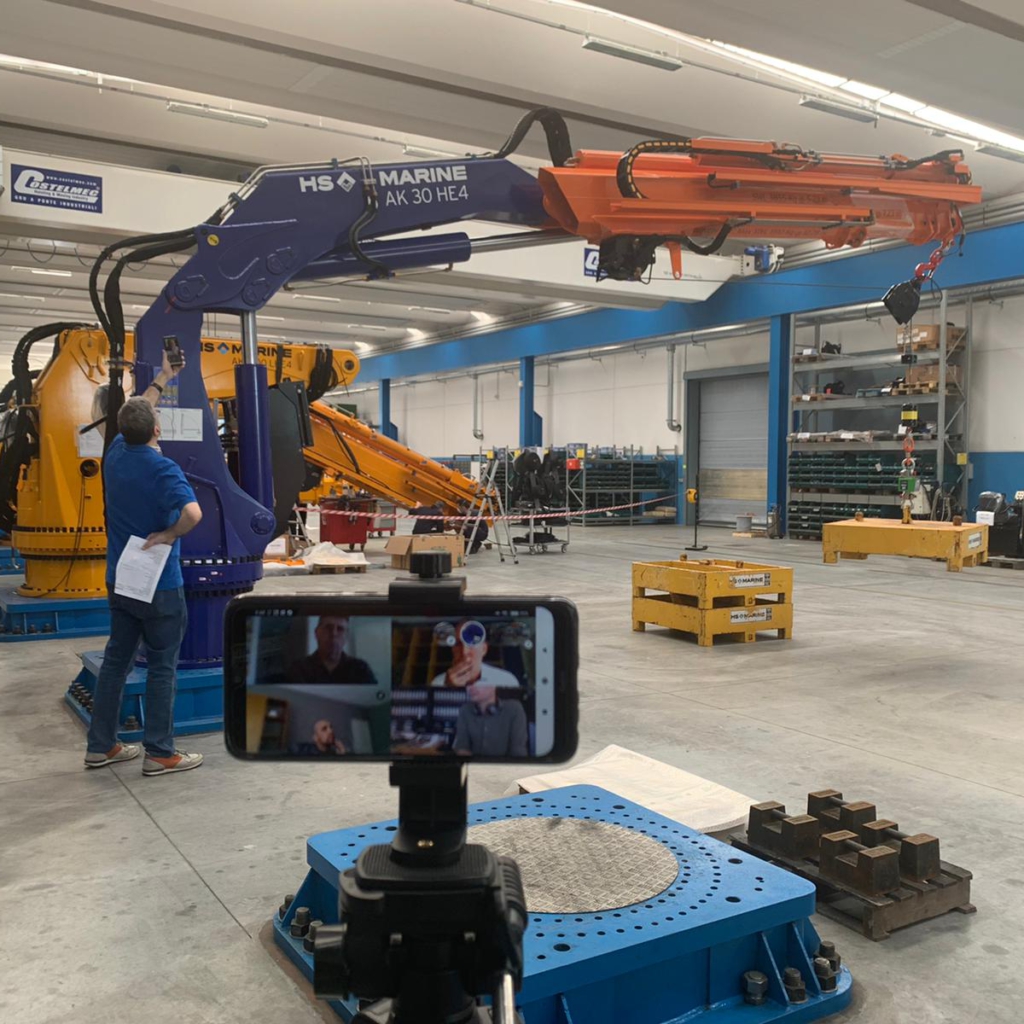

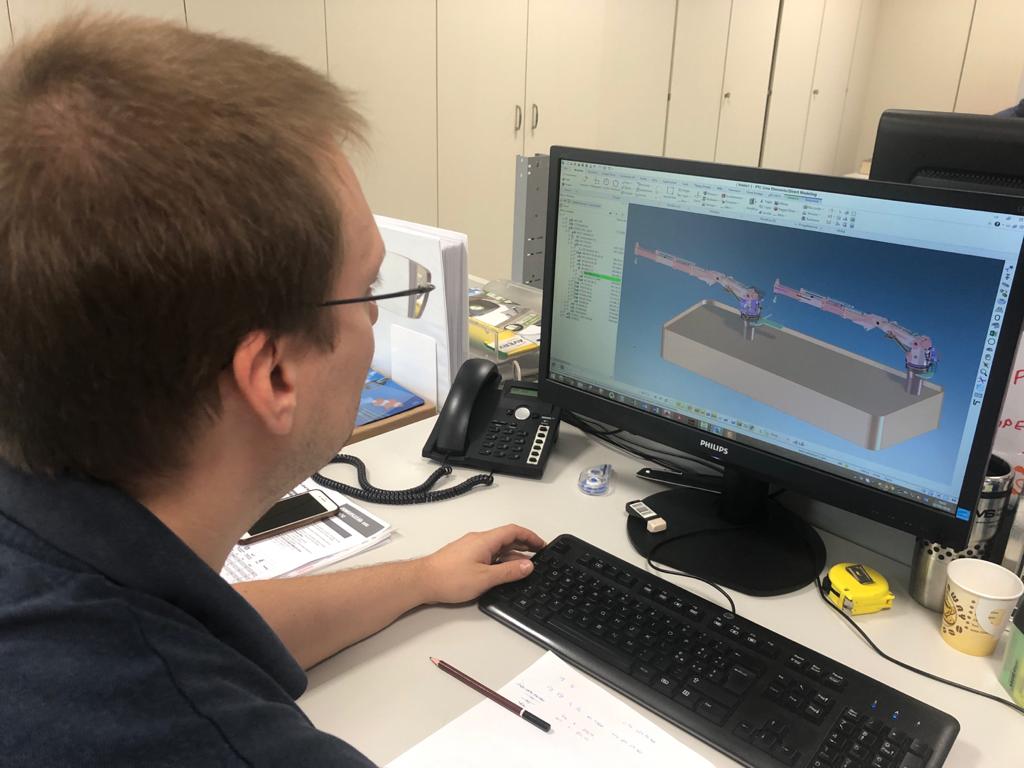

Remote Factory Acceptance Test

The Factory Acceptance Test (FAT) is a process that evaluates the equipment before shipment by verifying that the crane complies with its design specifications. FAT ensures that the components and controls are working properly according to the functionality of the equipment itself. As the name suggests, this testing is performed at the factory. If the customer is unable to reach HS.MARINE to attend the FAT, in collaboration with their Headquarters, we can support him during a remote FAT, giving him the opportunity to participate in every phase as if he were on site.